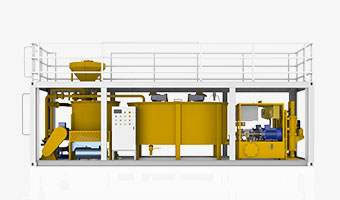

As a professional manufacturer of

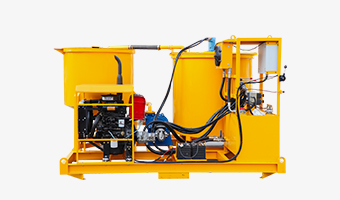

bentonite station with mixer, Wodetec is committed to providing tailor-made solutions for complex engineering scenarios such as tunnel construction, microtunnel/jacking/directional drilling projects, anchoring systems, dam construction, underground continuous wall/mud wall construction, and deep soil mixing. Our bentonite station with mixer series covers a variety of types such as piston, plunger and squeeze hose, diesel power and electric drive options to ensure that the station can operate stably under various extreme working conditions.

Our

bentonite station with mixer integrates stirring, mixing and grouting functions. Its unique design achieves a perfect fusion of cement or bentonite and water in the mixer through high-intensity turbulence generated in the pump casing. This high-shear turbulence effectively separates particles and promotes complete hydration to form a uniform and stable suspension. After mixing, the material is immediately transferred to the agitator, and the continuous action of the slow stirring paddle prevents the cement slurry from settling, while eliminating bubbles in the mixture to ensure the quality of grouting. Each device is equipped with a mixer and pump with matching capacity, working in conjunction with the agitated storage tank to achieve a nearly continuous production process.

As an important equipment in the field of modern engineering construction, the

bentonite grouting station is widely used in above-ground and underground engineering projects such as highways, railways, water conservancy and hydropower, construction projects, and mining. Its core function is to efficiently mix a variety of media, including but not limited to water, cement, sand, bentonite, various fillers, clay and silicate, and then use a plunger grouting pump to perform precise grouting or grouting operations to achieve key engineering goals such as waterproofing and plugging, tunnel lining reinforcement, foundation and rock reinforcement, and structural gap filling.

At present, Wodetec can produce a full range of bentonite station with mixer with piston, plunger and hose pumps. The mixer capacity ranges from 200 to 800 liters, and the agitator capacity covers 300 to 1200 liters. The pump flow rate can reach 0 to 130 liters/minute and the pressure can reach 0 to 100 bar to meet different engineering needs.

We sincerely invite you to contact us, visit our factory, and explore the bentonite slurry mixing and pumping solutions that best suit your engineering needs.