big size tunnel refractory gunite machine

The big size tunnel refractory gunite machine boasts three core advantages, making it the preferred equipment for tunnel refractory construction.

1. Low rebound, low dust, and environmentally friendly and efficient.

2. Reduced additive water volume ensures stability.

3. Improved density and strength, extending service life, and ensuring long-term tunnel safety.

The big size tunnel refractory gunite machine boasts three core advantages, making it the preferred equipment for tunnel refractory construction.

1. Low rebound, low dust, and environmentally friendly and efficient.

2. Reduced additive water volume ensures stability.

3. Improved density and strength, extending service life, and ensuring long-term tunnel safety.

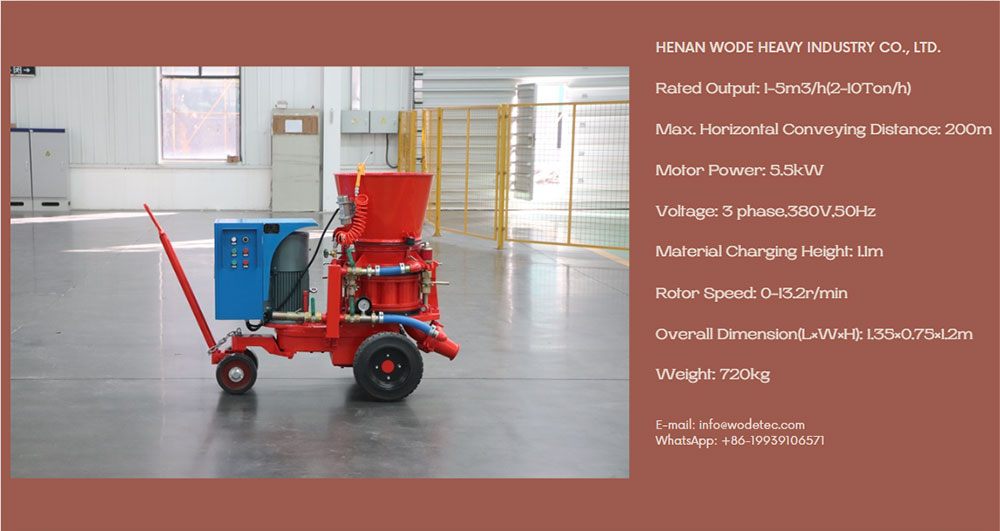

Big size tunnel refractory gunite machine parameters:

| Rated Output | 1-5m3/h(2-10Ton/h) |

| Max. Horizontal Conveying Distance | 200m |

| Max. Aggregate Size | Φ15 mm |

| Conveying Hose Inner Diameter | 51mm |

| Operating Air Pressure | 0.2-0.4MPa(29-58PSI) |

| Air Consumption | 8~9m3/min(285-325CFM) |

| Motor Power | 5.5kW |

| Voltage | 3 phase,380V,50Hz |

| Material Charging Height | 1.1m |

| Rotor Speed | 0-13.2r/min |

| Overall Dimension(L×W×H) | 1.35×0.75×1.2m |

| Weight | 720kg |

This big size tunnel refractory gunite machine is widely used in various tunnel types:

Transportation tunnels: Expressway and railway tunnels meet high safety and durability requirements.

Hydraulic tunnels: Water supply and diversion tunnels for water conservancy hubs, improving impermeability and corrosion resistance;

Mining tunnels: Mine transportation and ventilation tunnels, enhancing wear resistance and load-bearing capacity;

Urban underground tunnels: Subways and utility corridors, minimizing impact on urban life.