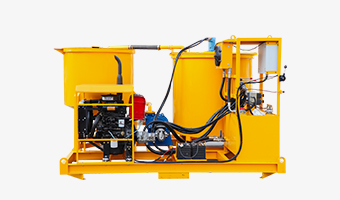

Recently, two 200-liter high shear grout mixers customized by our company for a Danish client have completed all acceptance procedures and are about to be shipped to Denmark. The smooth progress of this order demonstrates Henan Wode Heavy Industry Co., Ltd.'s professional expertise and global service capabilities in the field of grouting engineering equipment manufacturing, winning recognition from international professional engineering clients.

In November 2025, our company received a procurement inquiry from a Danish client who specifically requested 150-200 liter

high shear grout mixers and made clear requirements regarding delivery time in Denmark. Based on the client's business scenario analysis, their core business focuses on various drilling and underground engineering projects, including geological drilling, environmental drilling, core drilling, and hydrogeological drilling. These operations generally require grouting processes to reinforce the strata, seal leaks, and stabilize borehole walls to ensure construction safety and project quality. This procurement specifically addresses the essential grouting needs in daily construction, aiming to improve operational efficiency and compliance through specialized equipment.

As a company with over a decade of experience in manufacturing grouting equipment, we leverage our extensive industry experience to respond quickly and provide precise solutions to our clients, combining the core advantages of our high shear grout mixers.

Our company's independently developed and manufactured

cement grout mixers possess multiple core advantages, perfectly adapting to diverse drilling and grouting scenarios:

1. The high shear grout mixer employs a high-precision proportioning control system, accurately controlling the grout concentration to ensure construction quality in geological drilling foundation reinforcement, core drilling borehole wall stabilization, and other operations, aligning with customers' business pursuit of "robust and sustainable foundations."

2. The high shear grout mixer body is constructed from high-strength, wear-resistant materials, easily handling complex environments such as drilling in various hard strata and outdoor mobile construction, forming a highly efficient fit with customers' flexible transportation construction modes.

3. The 150-200 liter capacity design balances high production capacity with flexible adaptability, meeting the grouting needs of large-scale projects such as geological technical drilling and hydrogeological exploration, and also adapting to specialized operations such as pollution isolation and sealing in environmental drilling.

As a professional manufacturer covering the entire grouting engineering process, our company does not focus solely on the jet grouting mixer product, but rather has built a comprehensive system encompassing "mixing - transportation - grouting - supporting equipment." Our company boasts a complete equipment system, providing end-to-end solutions: In the grouting delivery and pressurization stage, it possesses electric, pneumatic, and diesel-powered high-pressure grouting pumps and high-pressure wear-resistant grouting pipe assemblies, capable of meeting long-distance, high-precision grout delivery requirements under varying pressure conditions; for grouting assistance and control, it is equipped with grout mixing and storage tanks, flow and pressure recorders, etc., ensuring grouting continuity and traceability of construction data, adaptable to precision grouting and large-scale operation scenarios; drilling and grouting supporting equipment includes small geological drilling rigs, fully hydraulic core drilling rigs, crawler-type multi-tube rotary jet grouting rigs, crawler-type anchor drilling rigs, and multi-functional engineering drilling rigs, forming an integrated "drilling-mixing-grouting" operation process, improving construction efficiency and stability.

Since its establishment, our company has always focused on the core technology research and development and production process optimization of

jet grouting mixer, relying on its own production plant to achieve independent control over the entire process from design, production to delivery. Our factory-direct sales model not only eliminates intermediaries and strictly controls costs, but also allows for rapid adjustments to production plans based on individual customer needs, ensuring fast and efficient delivery and fully meeting the diverse grouting operation requirements of different countries and engineering scenarios. For over a decade, our end-to-end grouting equipment has been successfully adapted to various grouting projects worldwide, including geological drilling, foundation engineering, environmental remediation, and hydrological exploration, earning widespread acclaim for its stable performance and superior quality.

The successful acceptance of this Danish order demonstrates the precise alignment between our high shear grout mixer product advantages, end-to-end supply chain, and international engineering needs. We will continue to improve the production and technological innovation of cement grout mixers, providing strong equipment support for drilling and grouting projects around the world.