CLC Concrete Mixing Machine with pump

CLC Concrete Mixing Machine with pump are widely used in a variety of fields, including basement and vault filling, sewer and drain filling, horizontal floor heightening, water tank and oil tank construction, vertical beam foundation ditch filling, prefabrication of foam concrete, insulation roofing, platform area filling and repairing, sound insulation and firewall construction, playground and runway construction, sound insulation layer and tunnel lining filling, as well as hollow wall panel pouring operations.

CLC Concrete Mixing Machine with pump are widely used in a variety of fields, including basement and vault filling, sewer and drain filling, horizontal floor heightening, water tank and oil tank construction, vertical beam foundation ditch filling, prefabrication of foam concrete, insulation roofing, platform area filling and repairing, sound insulation and firewall construction, playground and runway construction, sound insulation layer and tunnel lining filling, as well as hollow wall panel pouring operations.

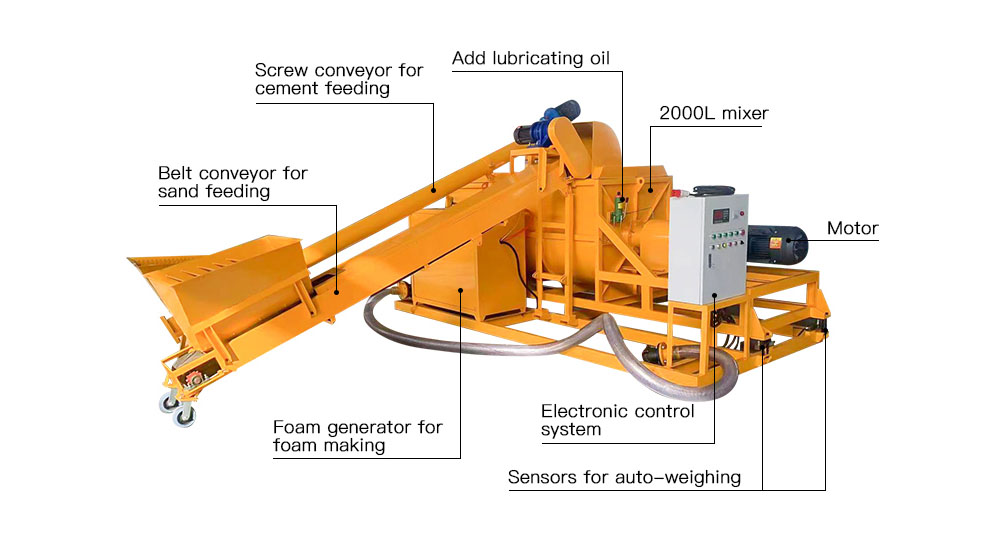

CLC Concrete Mixing Machine with pump parameters:

| Model | HWM2000 |

| Capacity | 20-30m3/h |

| Power | 30Kw |

| Voltage | 3 phase, 380V, 50Hz |

| Mixer volume | 2000L |

| Water pump | 50m3/h |

| Foam generator | 30m3/h |

| Measurement method | Cumulative measurement |

| Discharge method | Manual discharge |

| Belt conveyor | 300*3800mm |

| Screw conveyor | φ165*4000mm |

| Main part dimension | 4000*2050*1900mm |

| Weight | 1500kg |

Leave a message now and contact us to get the price of CLC Concrete Mixing Machine with pump for free. Henan Wode Heavy Industry Co., Ltd. is a foam concrete machine manufacturer that can be customized according to your needs. In order to recommend more suitable CLC Concrete Mixing Machine with pump to you, please clearly inform your needs:

1. How much output do you need? 5 cubic meters/hour, 10 cubic meters/hour, 20 cubic meters/hour, 30 cubic meters/hour or other?

2. What is the vertical conveying distance (meters) and horizontal conveying distance (meters) you need?

3. What is the voltage in your area? Is 3-phase, 380V, 50Hz okay?