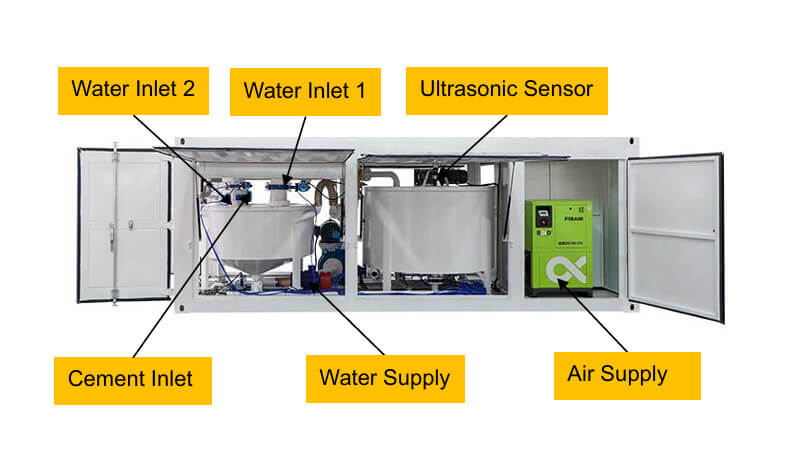

Full Automatic 30m3/H Container Grout Mixer Plant

The Full Automatic 30m3/H Container Grout Mixer Plant can work under the container silo. The HWMA30 automatic grouting mixing station is mainly used to prepare cement mixture (cement slurry) and bentonite slurry. Specifically, it obtains cement slurry through high-speed turbulent mixing of water and cement powder, or uses water and bentonite powder to prepare bentonite slurry for plastic mud.

The following are the parameters of the Full Automatic 30m3/H Container Grout Mixer Plant:

| Specification: | |||

| 1. Two modes of operation: fully automatic mode and manual mode.

2. Automatic cleaning system. 3. The preparation of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid component. 4. Can be placed directly in the 40ft cabinet. |

|||

| HCS17B Cement Silo | |||

| Volume | 17m³ | Conveying | 60t/h |

| Inlet Dia. | 100mm | Outlet Dia. | 325mm |

| Main power | 11Kw | Power supply | 380V, 50Hz |

| HWMA30 Full Automatic 30m3/H Container Grout Mixer Plant | |||

| Mixer | Agitator | ||

| Capacity | 1200L | Capacity | 2500L |

| Flow | 50L/s | Speed | 25r/min |

| Max. output | 30m³/h | Level sensor | Ultrasonic sensor |

| Power | 15Kw | Power | 3.0Kw |

| Air supply system | Water supply system | ||

| Flow | 540-1350L/min | Water tank volume | 960L |

| Pressure | 0.8MPa | Flow@lift | 11.11L/s@20m |

| Power | 7.5Kw | Power | 5.5Kw |

| External additive supply system | Flow@lift | 2.8L/s@18m | |

| Power | 1.5Kw | ||

| Power supply | 380V, 50Hz | ||

| Note: 1. All data are tested by water.

2. We can customize products according to your requirements. |

|||

The Full Automatic 30m3/H Container Grout Mixer Plant can work under the container silo. The HWMA30 automatic grouting mixing station is mainly used to prepare cement mixture (cement slurry) and bentonite slurry. Specifically, it obtains cement slurry through high-speed turbulent mixing of water and cement powder, or uses water and bentonite powder to prepare bentonite slurry for plastic mud.

We provide two specifications of container silos, 20 feet and 40 feet respectively. Among them, the HCS17B horizontal cement silo is designed according to the size of a 20-foot container. This design enables it to be placed directly in a standard container, greatly saving transportation costs. Moreover, multiple container silos also have the function of stacking.

Not only that, the Full Automatic 30m3/H Container Grout Mixer Plant is also very powerful. It can prepare ternary or quaternary composite mixtures. In terms of conveying components, each screw conveyor can undertake the task of conveying one or two liquid components and one solid component. Finally, the prepared cement mixture or bentonite slurry is transported to other equipment according to the type of geotechnical machinery used.