Chemical Dilution System Peristaltic Pump

In the chemical, pharmaceutical, and food processing industries, chemical dilution system peristaltic pumps are core equipment for ensuring efficient, safe, and stable production.

The key advantages of our chemical dilution system peristaltic pumps are as follows:

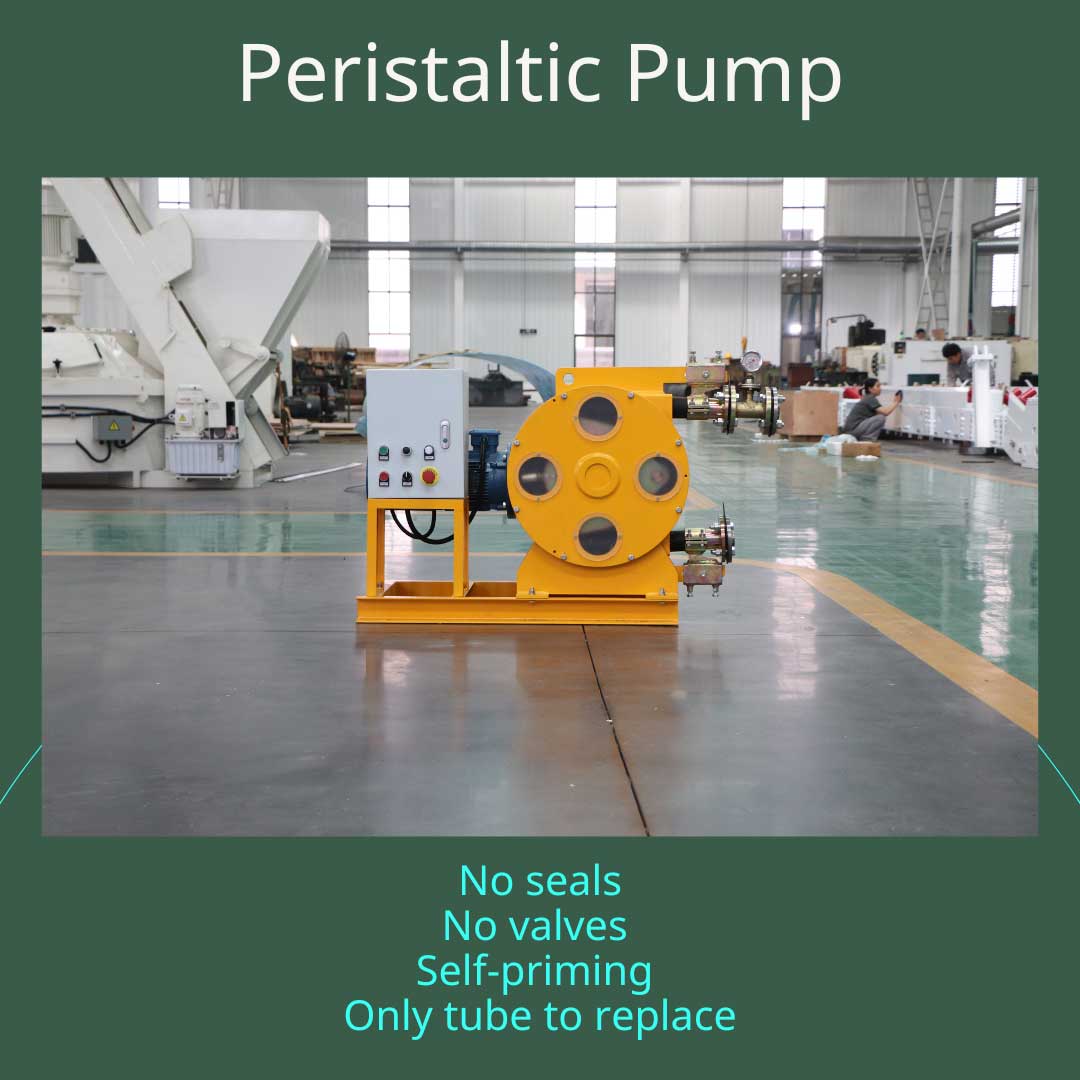

1. No seals/valves: Eliminates the risk of leakage from corrosive and volatile chemical reagents. Suitable for highly corrosive dilution systems, such as strong acids, strong bases, and organic solvents, this improves operational safety and stability.

In the chemical, pharmaceutical, and food processing industries, chemical dilution system peristaltic pumps are core equipment for ensuring efficient, safe, and stable production.

The key advantages of our chemical dilution system peristaltic pumps are as follows:

1. No seals/valves: Eliminates the risk of leakage from corrosive and volatile chemical reagents. Suitable for highly corrosive dilution systems, such as strong acids, strong bases, and organic solvents, this improves operational safety and stability.

2. Self-priming: Pumps from low-level containers without auxiliary equipment, quickly establishing stable fluid flow, simplifying system setup and operation, and improving operational efficiency.

3. Easy maintenance: Only the hose in contact with the reagent needs to be replaced. This simple operation requires no specialized personnel, significantly reducing maintenance time, cost, and effort. 4. Dry-running without damage: This handles dry-running scenarios such as reagent shortages and pipeline blockages, preventing component overheating and damage, ensuring continuous system operation, and minimizing production downtime.

5. Reversible: A simple operation switches between forward and reverse directions, enabling pipeline cleaning, draining, and fluid direction adjustment, preventing reagent cross-contamination and waste.

6. No contact between product and mechanical parts: Reagents flow only within the hose, completely isolated from mechanical components, ensuring reagent purity. This makes it suitable for dilution applications requiring extremely high purity, such as pharmaceuticals and electronic chemistry, while also extending the life of the equipment.

7. Able to pump products containing solids: The hose’s excellent flexibility and wear resistance allow it to pump liquids containing solid particles, avoiding pipeline blockage and equipment wear, expanding its application range (e.g., diluting reagents containing catalyst particles).

If you’re also looking for a suitable chemical dilution system peristaltic pump, please leave a message, and our engineers will assist you immediately.