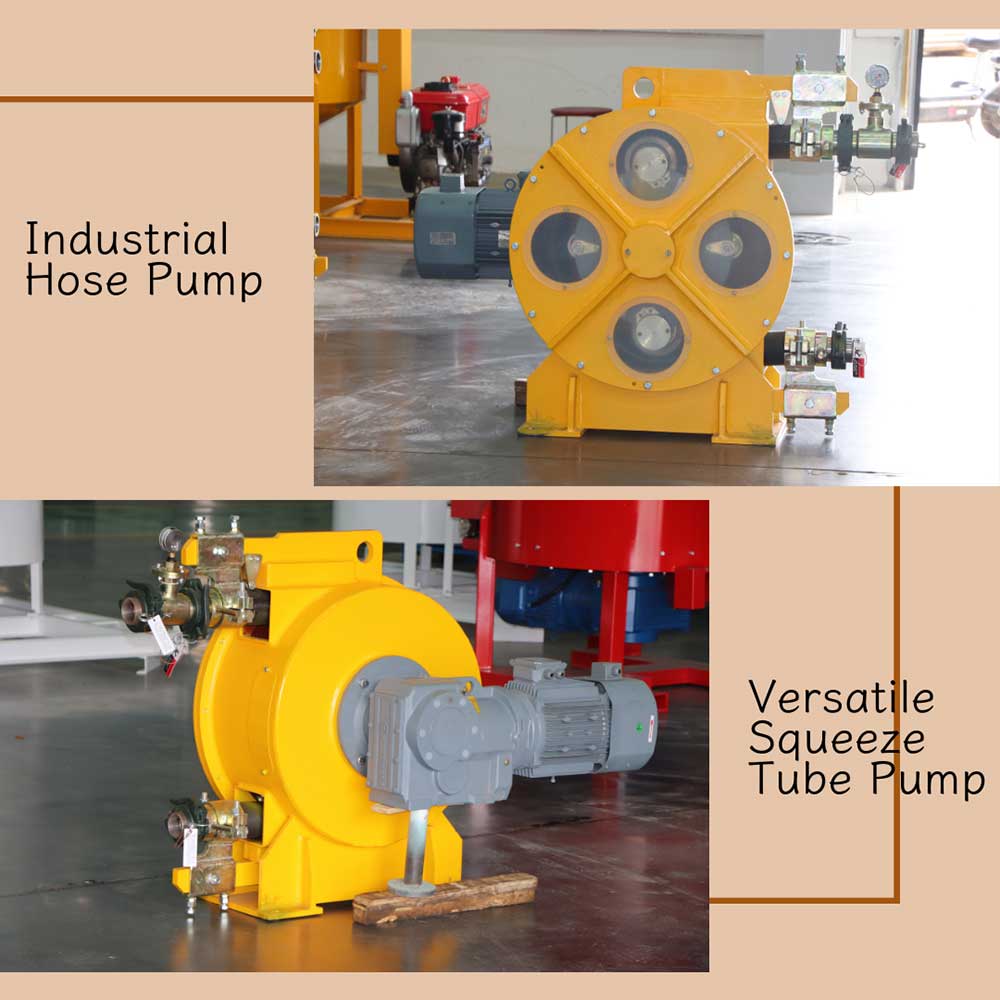

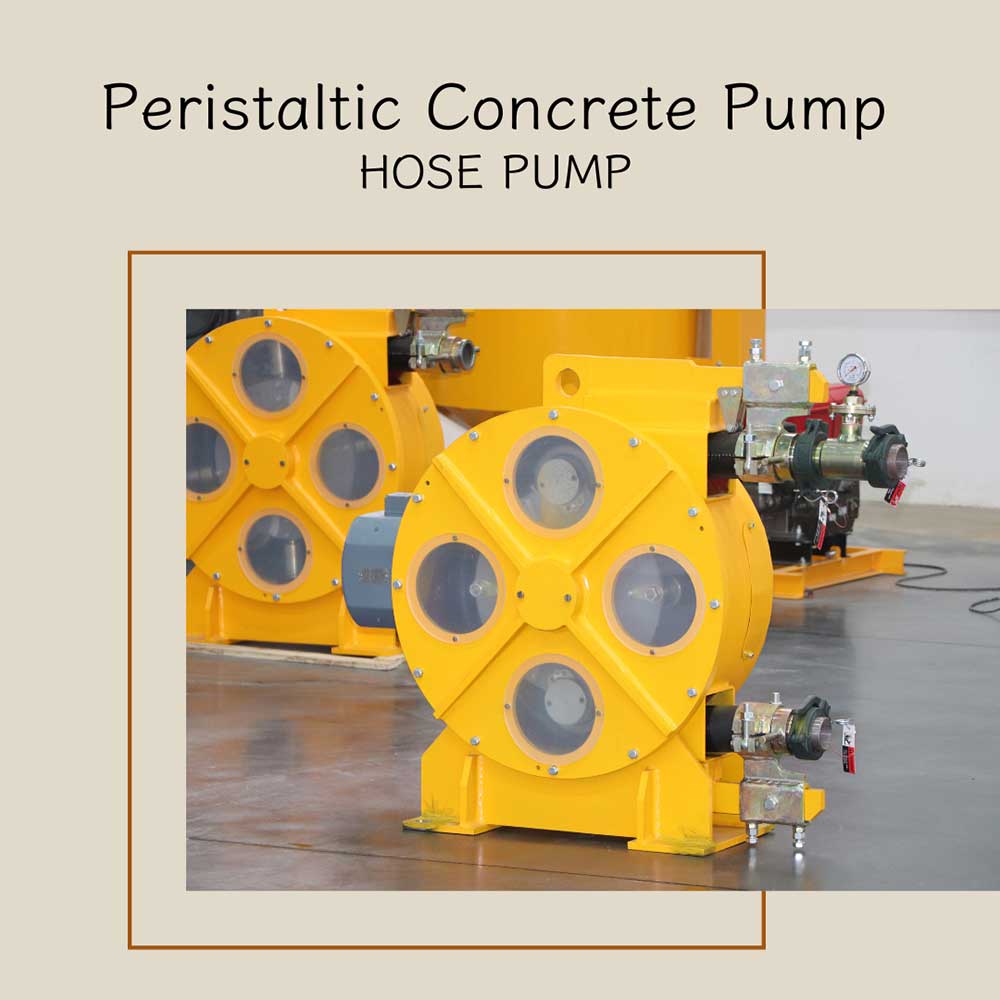

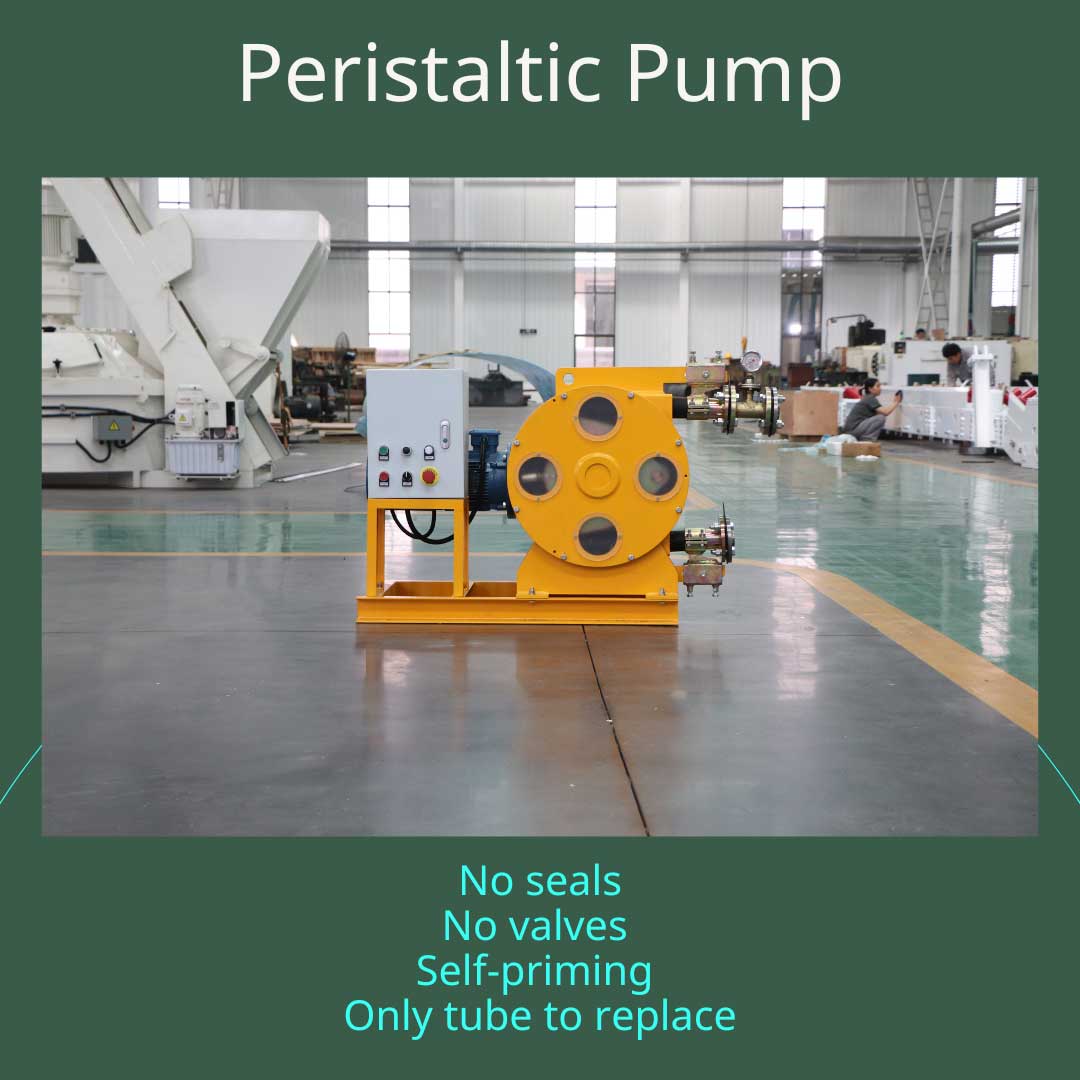

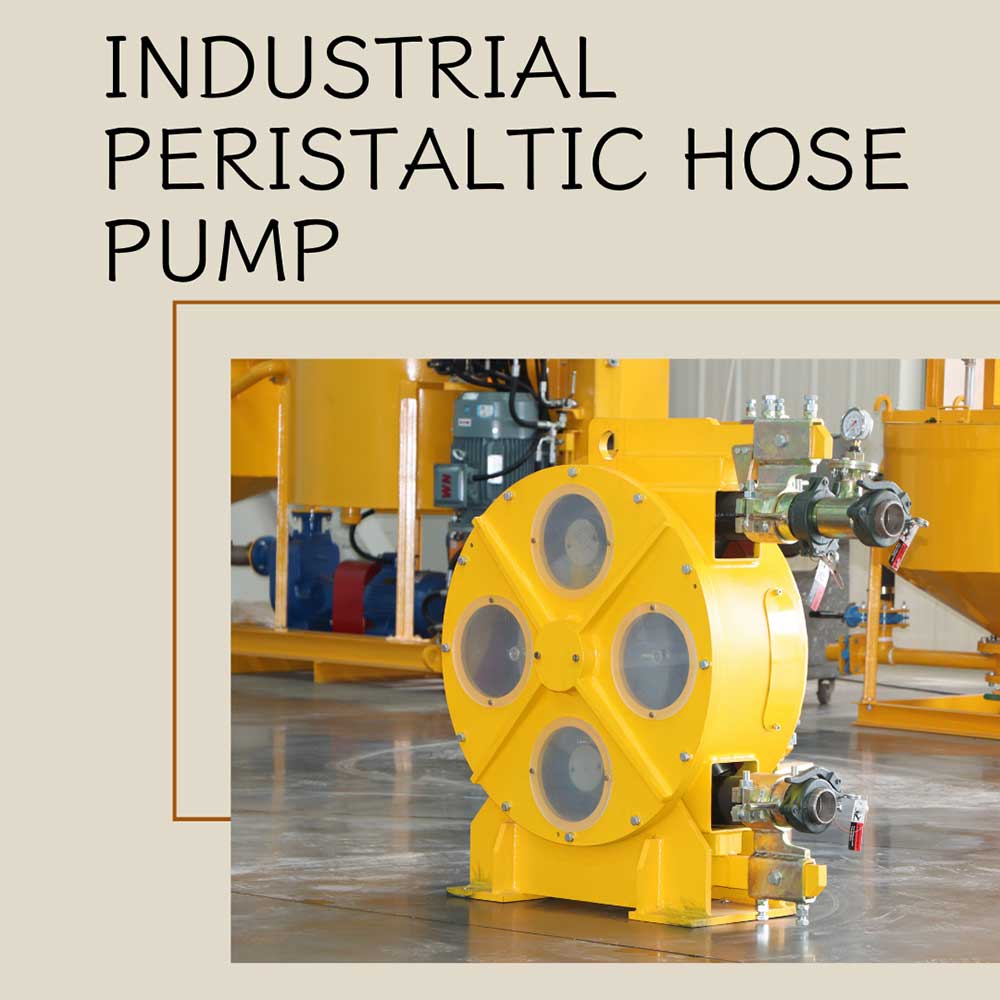

Industrial Hose Peristaltic Squeeze Pump

In the wastewater treatment sector, the Industrial Hose Peristaltic Squeeze Pump is a key conveying device. It can stably convey municipal wastewater or industrial sludge containing large amounts of solid particles and fibers without the need for additional filtration or pretreatment. It can also handle acidic, alkaline, and chemical wastewater, preventing secondary contamination caused by corrosion and leakage. Furthermore, the pump can precisely control flow rate by adjusting the speed to meet the needs of various processes, such as dosing and backflow.

The Industrial Hose Peristaltic Squeeze Pump is a highly adaptable fluid conveying device. Its core advantage lies in its ability to achieve fluid delivery through a motor-driven rotor that squeezes a flexible hose. Only the hose comes into contact with the fluid throughout the entire process, eliminating issues such as pump blockage, corrosion, and fluid contamination. It is widely used in complex conveying scenarios across multiple industries.

In the wastewater treatment sector, the Industrial Hose Peristaltic Squeeze Pump is a key conveying device. It can stably convey municipal wastewater or industrial sludge containing large amounts of solid particles and fibers without the need for additional filtration or pretreatment. It can also handle acidic, alkaline, and chemical wastewater, preventing secondary contamination caused by corrosion and leakage. Furthermore, the pump can precisely control flow rate by adjusting the speed to meet the needs of various processes, such as dosing and backflow.

In addition, the Industrial Hose Peristaltic Squeeze Pump has important applications in a wide range of industries. In the chemical and pharmaceutical industries, it can transport high-viscosity slurries, corrosive media, and sterile liquid medicines in compliance with GMP standards. In the food industry, the Industrial Hose Peristaltic Squeeze Pump can safely transport chocolate paste, fruit juice, and other raw materials, and the material meets food-grade requirements. In the mining industry, it is suitable for transporting high-wear ore slurries and smelting waste liquids, significantly reducing maintenance costs. In agriculture, it can also accurately measure pesticides and fertilizers to avoid resource waste and crop damage.